CDE – Communications Data Engineering GmbH |

| Email: | andreas.oyrer@cde.at |

| Internet: | www.cde.at |

Similar projects |

| System integration projects |

| Software intensive projects |

Soft- and Hardware Testing of devices used in the automotive industry is very important to achieve highest safety and quality standards. At the moment it is very difficult to re-use “real field” data for implementing efficient and representable test and simulation models. So the only way to test automotive systems is to do field tests on the real motor vehicle. The problem is that these field tests are not really reproducible due to real life conditions and external parasitic inductions.

All companies involved in the vehicle development are forced to integrate their components as fast as possible and bringing them into service due to the very stringent time to market and budget calculations. In case of fixing software bugs which can occur in the “field testing phase”, there is often no chance to get the vehicle back to the garage for error analysis and therefore it is nearly impossible to solve those kinds of problems without a very high time and cost effort. The DATVS will reduce the effort and time by 30-70% (based on the application) because all the “field testing bugs” can be simulated during the development and testing process. This will also increase the quality due to reproducible testing results.

Further challenges are the Functional Safety norms which are currently accomplished by a theoretical analysis with a more or less poor testing coverage on “real automotive systems”. Therefore the only right way is to design a development and testing system which is capable of providing engineers the components / systems in the lab without using any “real automotive system”. This system will include the original built in Automotive Hardware with originally equipped sensors and actors. These sensors and actors in combination with a controlled “Software Model” shall reflect a specified system part behaviour e.g. Transmission, Engine, Hitch.

AVL IODP supports the entire development process for road vehicles from office to lab to field by integrating real (hardware) and virtual (simulation models) development methods into one framework: Such an integrated development platform offers a seamless exchange of data from the concept phase to road testing. The proposed DATVS shall be integrated into the AVL IODP by means of well-defined tools like Matlab in order to take benefit of the different development information available in the Integrated and Open Development Platform (IODP). The DATVS solution shall therefore enhance the IODP platform for early HIL system – especially providing GPS information for the stimulation and testing of special off road vehicles and tractors with implements. The suggested HIL system addresses in particular the market for autonomous driving which is furthermore necessary to cope with the challenges for precision farming.

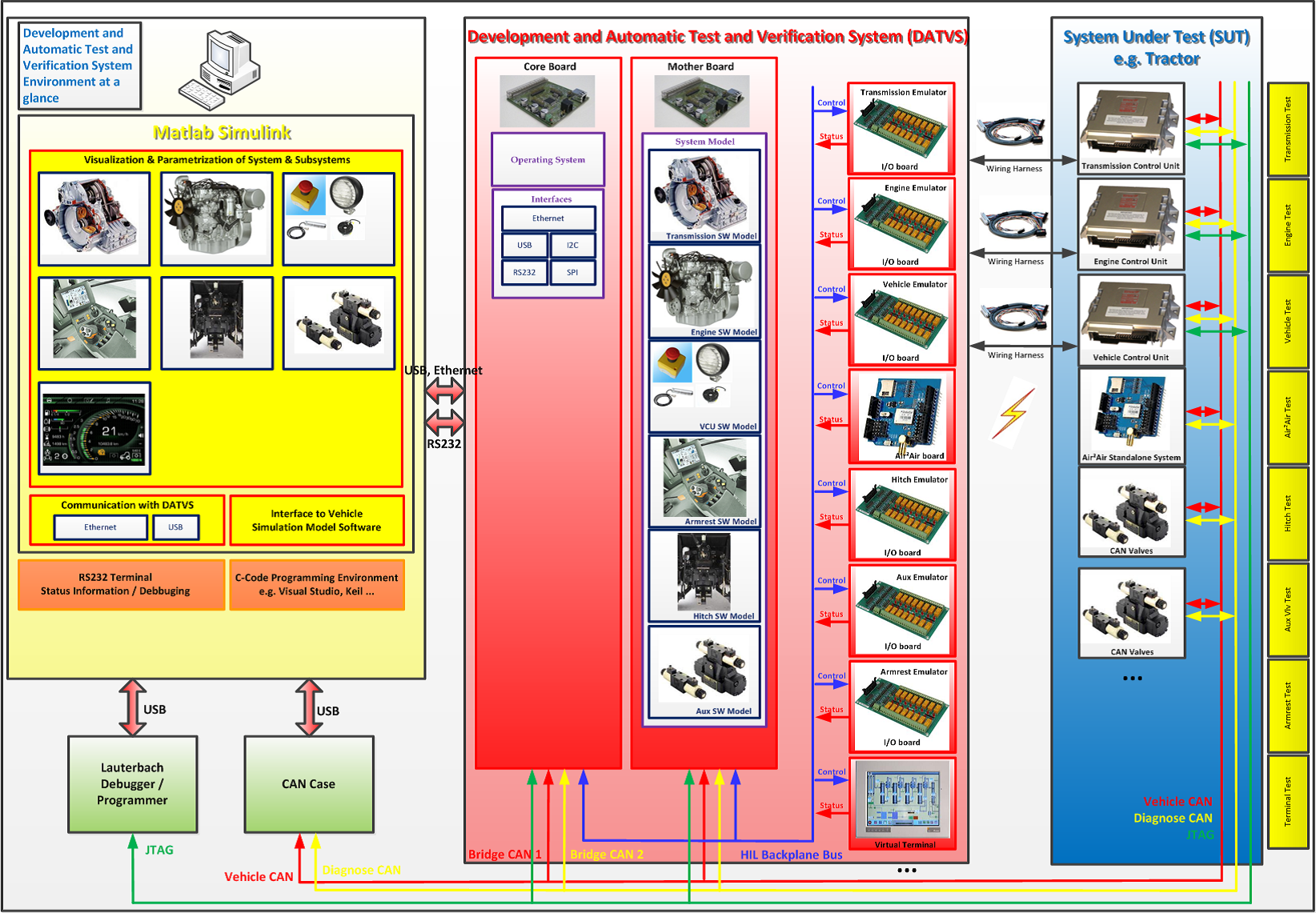

The figure shows the Development and Automatic Test and Verification System (DATVS) at a glance. It consists of the following major parts: Workstation (with Matlab), the DATVS with its Plug-in-modules and the System under Test, shown in yellow, red and blue respectively. The green components are provided externally and serve as Debugging / Programming Components for the Control Units